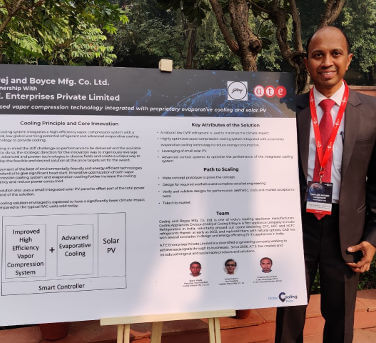

Godrej and A.T.E. chosen as a finalist for the global cooling prize!

A joint development of Godrej and Boyce Manufacturing Company and A.T.E. Enterprises

Videos

A.T.E. Company Profile

At A.T.E., we breathe technology. We produce and promote technologies that make your business more efficient and responsible. With innovation in our heart and soul, our products and services serve a wide range of strategic business areas that enhance your value chain. We started out with solutions for textile engineering and expanded to cooling and heating, wastewater, flow technology, intelligence of things, and value-added equipment for textiles, packaging, etc.Our Technologies

We are a value driven, world class group that aims to spearhead innovative and sustainable solutions for a brighter tomorrow. Following through on this mission, A.T.E. has developed 6 core technologies – textile spinning, internet of things for industry, wastewater treatment, heat exchange, print control and vision systems, and static and ink control. These core technologies have been developed through our domain expertise, assimilation of customer insights, research and development, as well as our commitment to addresses customers’ business and technology demands sustainably.History & Milestones

A.T.E was established in 1939 as a part of India’s freedom movement, and has since transformed into a multifaceted engineering group, offering world-class products and solutions spanning several industries. A.T.E.’s businesses encompass manufacturing, industrial sales, distribution and service, and has also gained expertise in handling turnkey projects.Network

A.T.E. is connected across India and throughout the world; we have an extensive sales and service network with regional offices in all metros across India, as well as an excellent agent network around the world. A.T.E. has also established a subsidiary - A.T.E. Technologies (Bangladesh) Private Limited, Dhaka – to take care of its operations in Bangladesh.Customers

A.T.E is proud to serve some of the leading companies in the world. With a base of over 5000 customers, our portfolio encompasses almost every industrial segment. Be it textile engineering, cooling solutions, Internet of Things for industry solutions, or any other business that we are in, we assist our customers from project conceptualisation through project implementation.- Company Profile

- Our Technologies

- History & Milestones

- Network

- Customers

Customer Testimonials